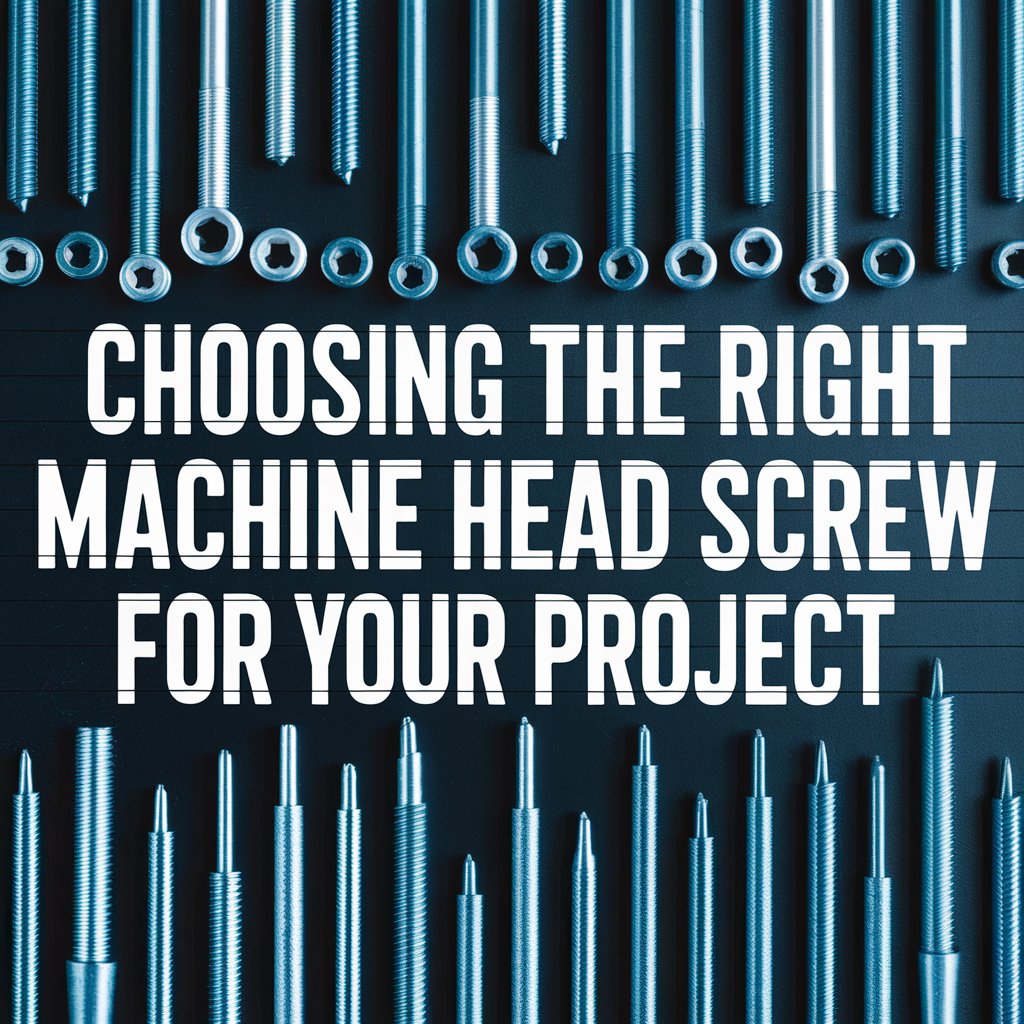

Choosing the Right Machine Head Screw for Your Project: Key Considerations

Have you ever wondered if the screws you use are suitable for the job? The selection of the corresponding screw type can be of crucial importance for the success of your project. You not only have to be the right size and the correct material, but your head style also plays an important role.

When you get the suitable machine head screws, your project places durable, safe and well manufactured. Let us examine some important considerations that you can make in your choice. Let us explore in detail.

Understand the requirements of your project

Before choosing screws, you need a clear understanding of your requirements. Different projects require specific features, from holding high -performance materials to securing sensitive components. Think about the type of support and what conditions you are with, such as moisture, heat or strong pressure. This helps to narrow down your options, save time and avoid mistakes.

Adjust the screw head type to your needs

The selection of the right head type can make the difference. Machine screws are available in several head types such as flat, round or hex, each of which offers unique advantages. Flat heads deliver a flush surface, round heads offer a clearer finish, and Hex heads enable high torque applications. Consider the aesthetic and functional requirements of your project when choosing the head type. The right choice not only looks good, but also well.

Consider the material for durability

The material of the screw directly affects durability and strength. The common materials include stainless steel, brass and alloy steel with unique properties that are suitable for certain environments. Stainless steel opposes rust and makes it ideal for outdoor applications, while Brass offers a decorative note with its pronounced color. Think about the surroundings that you encounter when choosing a material that can handle it and extends the lifespan of your project.

Rate the drive type for easy installation

Drive type affects the installation and removal of screws. Some joint drive styles include slit and witch drives, each offering a different level of handle and torque. Consider a drive type that offers easy access without projects for projects where frequent assembly and disassembly are required. The correct drive type minimizes the risk of wear during installation and keeps your work intact.

Factor the thread style for safe attachment

The thread style is another essential aspect. Some machine screws have coarse threads, ideal for softer materials, while other fine threads have hard materials for stronger attitudes. If you understand the requirements of your project, you can select the thread type that offers secure attachment. If you adapt the thread style with your material, you can prevent loosening over time and ensure a permanent fit.

Search for the right size and length

The selection of the right size and length is of crucial importance for the safe attachment. Machine screws are available in different lengths and diameters. So measure carefully before making a decision. Too short, and it couldn’t stop; Too long and the material could damage. Consider using a size manual or advice with a specialist to ensure that you select the correct dimensions for your requirements.

Take into account

Screws must be heat -resistant for projects that are exposed to high temperatures such as machines or certain electronics. Alloy steel and titanium are excellent for such applications because they maintain their integrity in extreme heat. By selecting temperature more, it helps to avoid melting or warp and offer permanent durability.

Rate the vibration resistance to the stability

If your project includes vibrations or movements such as automotive or machine applications, choose screws with improved vibration resistance. Some species have self -locked threads or additional features to prevent the loosening from loosening up by constant movement. By choosing vibration -resistant, it ensures that the structure remains safe even under stress.

Prioritize cost efficiency without impairing quality

Finally, look at your budget and cost efficiency of each option. While quality screws are a little more expensive, they offer durability and better performance over time. Investing in quality materials can reduce the risk of future repairs or replacement options, which makes you a cost -effective choice in the long term.

Analyze the torque requirements for optimal tightening

The torque plays a crucial role in securing machine screws without exceeding or causing damage. Different types have different torque specifications, especially in applications that require precision. Understanding the torque requirements ensures proper installation, preventing or weakening the material. Select the torque ratings that are suitable for reliable attachment to the requirements of your project.

The selection of the suitable machine head screws for your project is essential to achieve a safe, professional finish. From the selection of materials and the head type to the drive of style and finish, every factor plays a role in the performance and durability of your project. Take your time to choose with careful make sure that your project looks great and withstands the test of time. You can certainly choose the best for a well -done job by carefully considering these essential elements.